A Friday morning in mid-June that changed how I think about trust, verification, and workplace safety.

You can smell hot asphalt from three blocks away on a summer day. But when you’re standing on a roof next to 525-degree molten tar, that smell becomes everything: filling your nostrils, coating your throat, reminding you with every breath that you’re working with something that could end your career in seconds.

The mid-June sun beat down on the roof of Timber Ridge Junior High that Friday morning, and I could already feel sweat forming under my hard hat. We had a big job ahead of us, a 500-square roof replacement that would keep us busy for the next two weeks. I’d worked with plenty of crews before, but today brought a new face to our Arrow Roofing team. Darrell introduced himself as a journeyman roofer, spoke with confidence about his experience, and carried himself like someone who’d spent years perfecting his craft. We were all Local 49 union members, which usually meant you could count on solid skills and proper training. His handshake was firm, his tool belt organized, and he knew enough roofing terminology to sound convincing.

I believed him. Sometimes that’s all it takes, a firm handshake, the right terminology, and enough confidence to fill the gaps where experience should live.

Setting Up for What Should Have Been Routine

The morning started smoothly enough. Glenn, our foreman, orchestrated the crew with the quiet efficiency of someone who’d been running jobs for decades. J.B. got the mops and mop carts ready for the asphalt. Wes and Mitch were grabbing rolls of felt, testing their hooked utility knives, ready to cut and ‘fly’ felt into the hot, adhering it to the roof deck. The familiar symphony of a roofing crew at work: the scrape of tools, the thud of materials, the occasional joke cutting through the morning air. We hauled materials, set up equipment, and fell into the familiar rhythm of roof work. Darrell seemed to know his way around the tools, asked the right questions, and positioned himself naturally within our crew’s workflow. When it came time to fill the hi boy with hot asphalt, Dave, one of our most seasoned crew members, volunteered to work the ground while Darrell and I handled the rooftop duties.

This should have been routine. I’d done it hundreds of times before. At 74% of a journeyman’s wage, making $24 an hour, I was experienced enough to handle the technical side without thinking. Get the hi boy in position. Open the top. Lower the stinger into the container. Test the pull ropes to make sure everything moves smoothly. Wait for the ground person to fire up the pump motor. Then pull the rope to start the flow of hot asphalt.

Why Every Safety Step Exists for a Reason

The process exists for good reasons. Hot asphalt is heated 500 degrees. And our seasoned crew ran it hotter, knowing full well that it flashes, catches fire, between 525-550 degrees. This is the material that doesn’t forgive mistakes. It sticks to skin, burns deep, and leaves scars that serve as permanent reminders of careless moments. Every step in the sequence protects both the worker and the work itself.

I positioned myself at the edge where Darrell had brought the hi boy. I assumed he’d opened the lid. The pull ropes felt good in my hands, no tangles, no resistance. Everything checked out on my end. I trusted that Darrell had done his part.

“Ready down there?” I called out to Dave.

“All set!” came the confident reply from our trusted ground man.

The pump motor roared to life from below, and I pulled the rope.

When Trust Becomes Dangerous

Instead of the controlled flow of asphalt into an open hi boy, chaos erupted. Hot asphalt sprayed everywhere as it hit the closed lid of the container. Darrell had brought the hi boy to the edge but completely failed to open the lid, the one job he had in this operation. Molten material splashed in all directions, defying gravity as it sought any surface to cling to.

Both my arms caught the worst of it. Hot asphalt found its way past my sleeves, searing skin with the kind of heat that makes time slow down and your brain struggle to process what’s happening. The pain hit immediately, sharp, intense, and spreading as the material cooled and hardened against my flesh. It was like being branded with liquid fire.

I dropped the rope and stumbled backward, adrenaline flooding my system. Dave killed the pump motor immediately when he saw what was happening, but those few seconds felt like hours.

The Aftermath: Water, Anger, and Consequences

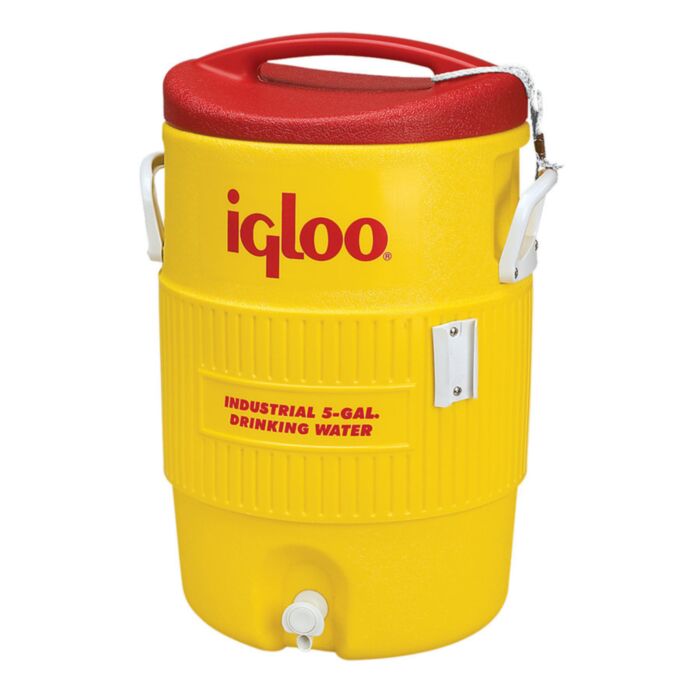

Glenn, realizing what happened, grabbed the only water on the roof, a 5-gallon Igloo, our only water for the day, flipping off the lid and dumping it on my arms.

Dave booked it up the roof, after shutting down the pump motor, screaming a stream of obscenities at Darrell.

Glenn, the quietest man I knew on a roofing crew, grabbed him by his shirt, threatening to pitch him off the roof. Mitch and Wes held back J.B. and Dave. Me? I was in shock, Glenn shoving me over into the shade to cool down and relax. My arms were on fire, at spots. And the crew shut down the job site.

Darrell was never heard from again, blacklisted from Local 49 by Glenn, Arrow Roofing, and our superintendent.

The burns healed over the following weeks, leaving marks that still catch my attention in the mirror. They remind me of that mid-June Friday morning when I learned an expensive lesson about verification and trust.

Darrell wasn’t a journeyman. His experience existed mainly in his imagination, padded with enough borrowed knowledge to sound convincing during casual conversation. But hot asphalt doesn’t care about smooth talking or confident handshakes. It demands real competence, backed by genuine experience and respect for proper procedures.

At least it happened on a Friday. That gave me the weekend to start healing before facing another work week, a small mercy that probably made all the difference in my recovery time.

I don’t harbor anger toward him. Everyone starts somewhere, and The construction industry has always attracted people trying to fast-track their way to better wages. But that day taught me the difference between trusting people and trusting processes. People can disappoint you, lie to you, or simply lack the skills they claim to possess. When we follow processes correctly, they protect everyone involved.

Building Better Safety Habits

Now I verify everything myself. I look before I leap, check before I trust, and confirm before I commit. It takes extra time, but time spent on verification never compares to time spent healing from avoidable mistakes. On every job since, I’ve made it my responsibility to double-check the basics, even when working with people I trust completely.

The scars on my arms tell a story about the price of misplaced trust, but they also remind me of something more valuable: the importance of taking responsibility for my own safety, regardless of who else claims to know what they’re doing. And I’m grateful it happened on a Friday, giving me those crucial weekend days to begin healing.

Sometimes the best lessons come wrapped in pain, delivered by people who never intended to teach us anything at all. And sometimes those lessons stick better than anything you’d learn in a safety meeting because you can still smell the asphalt when you think about them.

Building Your Safety Awareness Daily

I can’t tell you what safety protocols to follow on your job site, only share what years of roofing experience reveal to me.

Start this week: Verify one safety step you normally take for granted. Take that extra moment to double-check before proceeding.

Build your network: Talk to experienced crew members about close calls they’ve had. Learn from their mistakes before making your own.

Create systems that work: Develop personal safety checklists for high-risk operations, even when working with trusted colleagues.

Notice what happens when you slow down instead of rushing toward completion. Watch how your awareness changes when you verify processes instead of assuming others followed them.

Your future self, the one who goes home safe every day, grows stronger with every safety step you verify yourself.

Related Posts

- 8 Shocking Roof Safety Statistics You Won’t Believe – Hot tar burn statistics and prevention

- Burn Injuries among Roofers – 105 roofers burned in Oklahoma from 1988-2006

- Roofing Heat Hazards – California safety guide for hot tar work

- Construction Fatality: Roofer Falls 18 Feet from Wet House Roof – OSHA fatality investigation

- Falls Campaign 2022: Making Research Work – CDC research on construction fall prevention

Related Safety Resources:

- Roofing Contractor Magazine Blog – Industry magazine covering safety and accidents

- NIOSH Construction Safety Blog – Official workplace safety research and prevention strategies

- OSHA Real Stories – Official workplace accident narratives

- CPWR Construction Safety Research – Center for Construction Research and Training

- JobNimbus Safety Blog – Roofing safety content and accident prevention

- RoofSnap Safety Resources – Roofing safety training and industry standards

What’s your biggest safety concern on job sites? Have you ever had a close call that changed how you approach safety? Share your story in the comments below—I’d love to hear how you handle dangerous situations and the lessons you’ve learned.

What’s your biggest safety concern on job sites? Have you ever had a close call that changed how you approach safety? Share your story in the comments below—I’d love to hear how you handle dangerous situations and the lessons you’ve learned.

About the Author

Joe Class III is a storyteller using active voice to capture everyday events in natural language, exploring how ordinary work moments reveal extraordinary truths about trust and responsibility. He is a former union roofer with Local 49, having worked on commercial and residential projects throughout the Pacific Northwest. “The best safety lessons come from real experiences, not safety meetings.” When Joe’s not writing about construction work, he’s probably checking safety protocols twice.

Categories: Construction, Safety, Personal Development

Tags: roofing safety, workplace safety, union work, construction stories, safety protocols, job site accidents, roofing experience, workplace trust, safety verification, construction industry

Share this post:

- Facebook | Twitter | LinkedIn | Instagram

Hashtags: #RoofingSafety #WorkplaceSafety #ConstructionStories #UnionRoofer #SafetyLessons

Leave a comment

Leave a comment